Challenges And Solutions For Embroidery Digitizing

There are numerous companies online that offer vector art and embroidery digitizing services. The digitization industry is prospering in a fast pace, and so the related work it necessitates is expanding.

But, finding one embroidery digitizing company that meets your requirements and requirements can become a little bit intimidating. Moreover, because the industry itself features its own form of creativity and subtlety.

Table of Contents

The amount of detail in the software to the particular elements on a material is crucial, as is the work in each section.

When getting a wonderful embroidery art completed, the primary focus is finding a reliable business. It is possible to locate a digitizing service that is reasonably priced, dependable and guaranteed results is the trinity.

Extensive knowledge of the digitization industry is necessary when selecting a service to perform your requirements. Before that requires that you understand the intricacies of digitizing companies. You can gain a lot of insight with just a little research online.

For a top-notch, customer-centered digitizing service that meets or exceeds your expectations and offers cost-effective solutions, look no further than Digitizings.us.

We are the undisputed industry leaders when it comes to providing complete vector art and cutting-edge logo digitizing services. Having been steadfastly dedicated to providing holistic digitizing services for generations, we have set a benchmark in the market.

Digitizings.us focuses on art products that are creative. We have the finest digitizers, artists, and illustrators in the business, and our detail-oriented team offers the latest in logo embroidery digitizing and vector art distribution. We work hard to continually provide the best embroidery digitizing services and most cutting-edge vector art.

Major Challenges In Embroidery Digitizing

With Digitizings, our familiarity with the intricacies of the digitizing industry places us in a position to tackle some of the challenges our findings show most digitizing companies are likely to experience.

We also talk about the aspects directors will be able to adapt to when facing these same challenges.

One of the most widespread troubles held by the digitizing profession is the frequent occurrence of thread break issues. This problem is, in fact, a recurrent issue.

Beginners or new entrants to the digitizing needlework industry might find it difficult to manage the issue of continual thread breakage. We aim to shed light on the major causes of thread breaking, how to remedy the issue to have your embroidery machine running in no fuss.

Prevent Thread Break Problems In Machine Embroidery

As its name implies, during the needlework procedure, when needle thread breaks, it can be really annoying. For example, for the craftsmen who are diligently involved in the various designs of the embroidering procedure. This problem has been the most common among the problems that hinder a smooth needlework process.

A smart way to navigate thread breaks is to understand how to mend them. Thread fractures can range from simple to complex, and therefore each kind of repair needs a different type of technique.

Therefore, it is essential to know and understand the type of thread fracture you have before attempting to mend it. This will spare you time to undeceive yourself when you stumble upon a similar problem during additional time.

Types Of Thread Breaks

Knowing the various kinds of thread or strand breaks you may encounter during the embroidery digitizing process can be beneficial in successfully executing the process. The four main kinds are shredding, clean breaks, popping out, and false breaks.

Machine embroidery lovers use shredding thread tensile strength to break threads. Several reasons cause shredding thread, such as the needle eye being too small to fit the thread, the stress and friction generated by needle and thread use, and more. For this reason, this typically occurs when the needle eye is an unnecessary size for the thread.

If your thread becomes separated cleanly, it is a clean break. This will occur if the embroidery machine is left with too many thread tails for consecutively pulling yarn to form a stitch. It is vital to make sure the path of the thread is fully clear so that the thread glides easily.

In so doing, when the embroidery needle is running, if the thread pops out of the eye of the needle, that’s known as a pop-out thread issue. If the thread breaks, the top end of it is connected to the fabric. If the break registers in the embroidery machine, it is not meant to occur.

Improper tension is a major cause of false thread breaks in embroidery machines.

Thread breaks: Common issues.

Looking for the type of thread break is the key to subsequent machine embroidery. When looking at the type of thread break, it’s rather simple to distinguish the rest. Let’s take a closer look at the common thread breaks that are very common in machine embroidery processes.

The constituent of most thread breaks is a bad stitch lifecycle or inappropriate needle gauge. Additionally, they may be brought on by the failure of the needle plate, needle injury, or thread breaking. The height of the press foot, incorrect timing, improper needle depth, and low oil on the rotary hook may also lead to a lot of thread breaks.

By selecting durable and strong thread types, embroidery digitizers can help to avoid many common and unavoidable problems. Polyester and rayon are two of the most well-liked thread varieties in embroidery artwork.

Polyester is most advised because of its sturdiness, durability and resistance to color fading. Each embroidery digitizing issue is connected to the varying actors in the environment, but incorrect stitching causes the most recurring break problems.

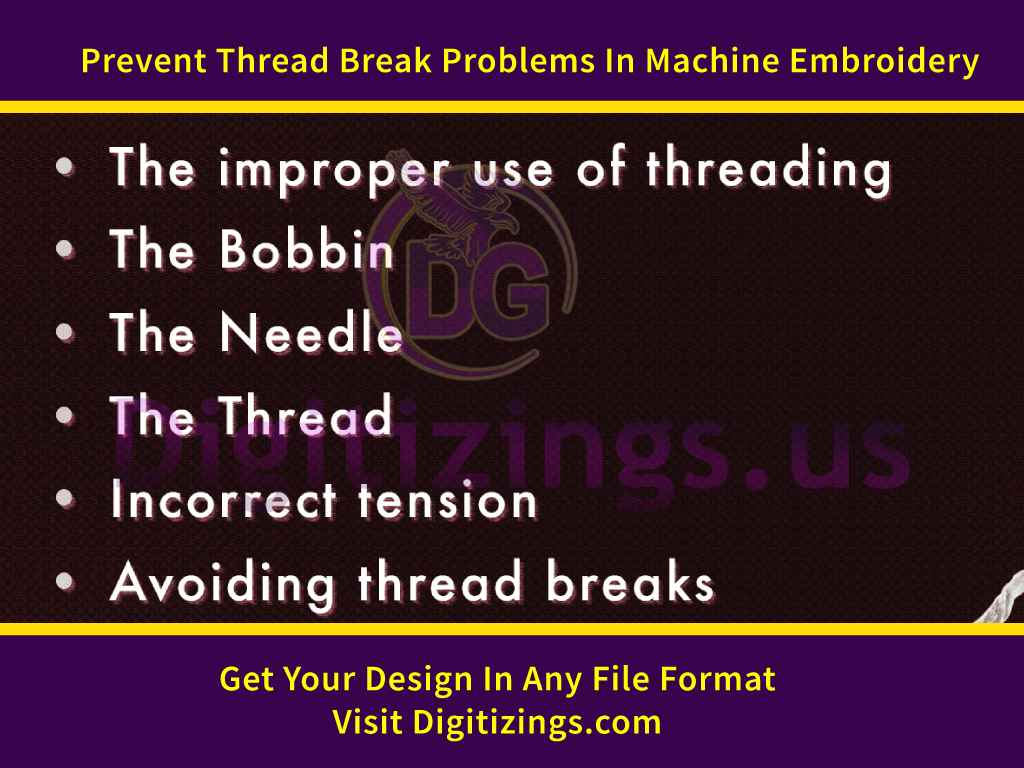

The most common problems can be listed as

• The improper use of threading

• The Bobbin

• The Needle

• The Thread

• Incorrect tension

• Avoiding thread breaks

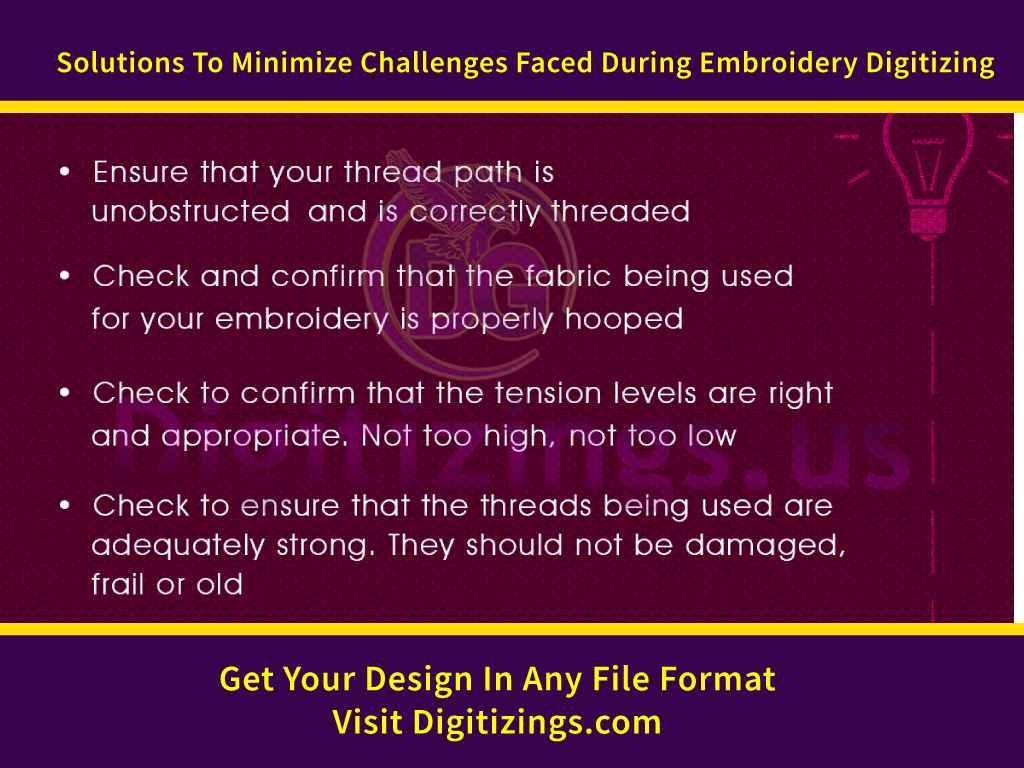

Solutions To Minimize Challenges Faced During Embroidery Digitizing

First, examine the source of the issue. Get rid of the major sources of thread breakage, from diagnosing beforehand to proactively dealing with the difficulties as they arise. when creating a list, ensure that you create it once you experience the challenges.

- Check that the thread path you have provided is free from any obstructions and that it’s attached correctly to the hoop.

- Make sure the inserted into loop threading is level and properly controlled.

- Your needlework should be minimized in areas that are demanding and overcompensating in areas where it is redundant.

- Make sure that all the threads being used are sound and suitably strong.

- They should be in good condition with no tearing, wear, or weakness.

Overlooking the absence of accomplished digitizers amongst the main problems with the embroidery procedure, one cannot avoid mentioning the difficulty experienced during the process.

These incredibly effective experts make the main difference when it comes to developing a excellent end result.Digitizers used to play a crucial role in minimizing numerous risks associated with the embroidery digitizing procedure.

Achieving a high degree of design-consciousness and keeping the designer intact are additional struggles in step with digitizers. Furthermore, they will need to invest in suitable and innovative embroidery machinery, as well as perfect work environments.

Digitizings.us, a skilled and expert vendor, has a state of the art facility that can undertake orders for individual orders and bulk customers. Their specialists use top-tier embroidery machine software and innovative approaches to accomplish your vision.